OUR PRODUCTION PHILOSOPHY

We are continuously improving

There are 50 different stages in the production process of a Trangia stove. Altogether, they make up a total of six minutes. With 60 years of experience and constant development work being carried out on both tools and methods used, we are getting pretty good at what we do.

And we are continuously striving to develop new and better ways to manufacture our products. With our limited factory space we are forced to constantly streamline and make our production more efficient, to be able to keep up with the growing demand. Our production is a combination of traditional machinery and modern technology. Some of our machines are old faithful servants that have been with us since the 1950s.

We upgrade and adapt our old work horses as long as they are functional and it is safe to do so. Our modern robots help facilitate the workflow in the factory and has drastically reduced the changeover time. All our supervisors and operators are very experienced machinists and there are very few problems we cannot solve in-house.

“We are proud that our production is based in Sweden, we intend to keep it that way."

Our production in photos

FLAT DISCS – Most of our raw material comes to Trångsviken as flat discs.

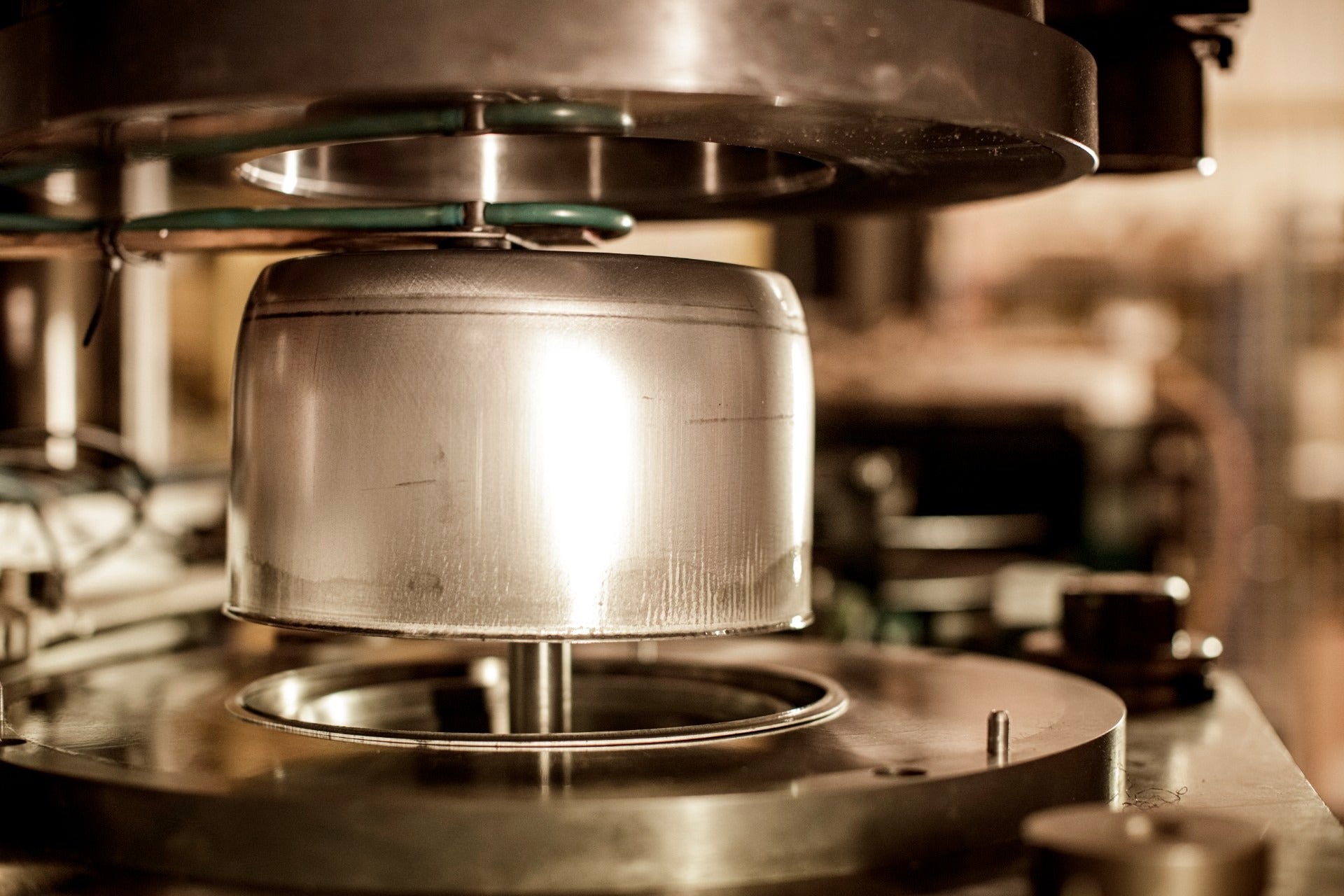

HIGH PRESSURE – The pot is shaped with 50 tons of pressure in an hydraulic press.

TEAM – Our team has grown from 20 to almost 100 people in 4 years.

CONTINUOUS IMPROVEMENTS – We consistently streamline and make our production more efficient and sustainable.

HANDLES - In the automatic press, strips of the aluminum alloy are transformed into handles

DETAILS – No details of improvement is too small such as softening a sharp edge on the kettle spout.

THE SPIRIT BURNER – Assembled from 8 different parts. Barely visible to the user, there is a cotton wick inside which gives the burner its effect.

MADE IN JÄMTLAND – Trångsviken is where it all started and we intend to keep our manufacturing here.